Elevate Your Bottling Excellence with multiFeeder's Revolutionary Technology

Welcome to the future of bottle packaging with multiFeeder - your gateway to unparalleled efficiency, sustainability, and flexibility.

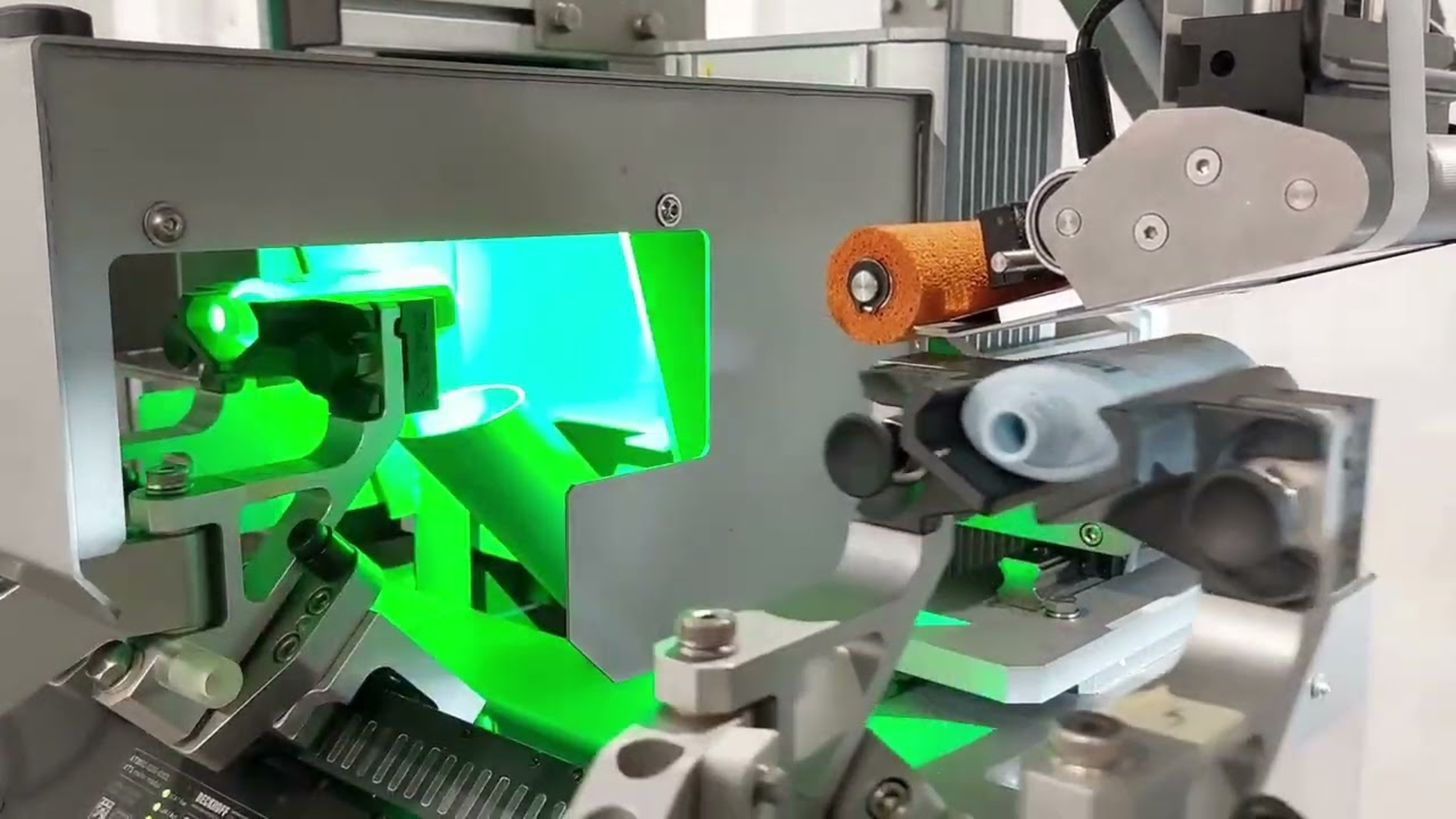

Our cutting-edge technology, embodied in the:

MULTI – material,

MULTI – function,

MULTI – format solutions,

revolutionizes the way you handle glass and plastic bottles.

Welcome to the future of bottle packaging with multiFeeder - your gateway to unparalleled efficiency, sustainability, and flexibility.

Space Savings: Streamline your production line by eliminating unnecessary equipment and buffer conveyors.

Increased Efficiency: Our robotic system optimizes processes, enhancing overall production efficiency.

Reduced Maintenance Costs: Minimize downtime and maintenance expenses with multiFeeder's reliable and low-maintenance solution.

Zero Changeover Times: Experience practically zero changeover times, ensuring uninterrupted production.

Customer Empowerment: Customize and add new format parts independently, putting you in control.

Traceability and Serialization: Ensure constant traceability of bottles and leverage serialization for track and trace capabilities.

The multiFeeder machines are multi-material so they can work with a wide range of materials such as plastic, glass, cardboard, metal, sustainable ultra-lightweight bottles and others.

Of course, we offer technical assistance from any of the group's centers. We also have the option of remote assistance.

Maintenance is simple and intuitive, and we also offer after-sales service to accompany the process.

The speed of the machine depends on the needs of the customer. We can work up to a maximum of 400 bpm.

No, our aim is always to make the machine easy to operate and use. The machine is controlled from a screen with a very intuitive and visual system.

In addition to container unscrambling, any other function can be added. For example: labelling, track&trace, ink coding, laser coding, rinsing, inspection, filling and more.

Of course, we adapt to the characteristics of each company's production line.

Unlike the pickFeeder, the multiFeeder allows you to integrate more functions in addition to unscrambling containers.

We work with all sizes as it can be customized. We have standard and XL machines depending on the needs.

Yes, this equipment is characterized by its flexibility. It automatically adapts to the formats thanks to its vision system, so adding new formats is not a costly or time-consuming operation.

Thanks to its intelligent vision system, the multiFeeder adapts to all types and shapes of containers: jars, vials, bottles... Automatically and without any format changeover.

Our range of models, featuring one to four robotic units, adapts seamlessly to your project's unique needs. Automatic format changeovers and extraordinary versatility enable multiFeeder to handle an infinite range of products, customized to meet your specific requirements.

Revolutionize your bottling operations with multiFeeder's future-proof technology.

Whether you need one robot or a team of four, our system handles bottles up to 3L at a remarkable speed of up to 300 bpm. Welcome to a new era of efficiency, sustainability, and flexibility with multiFeeder!