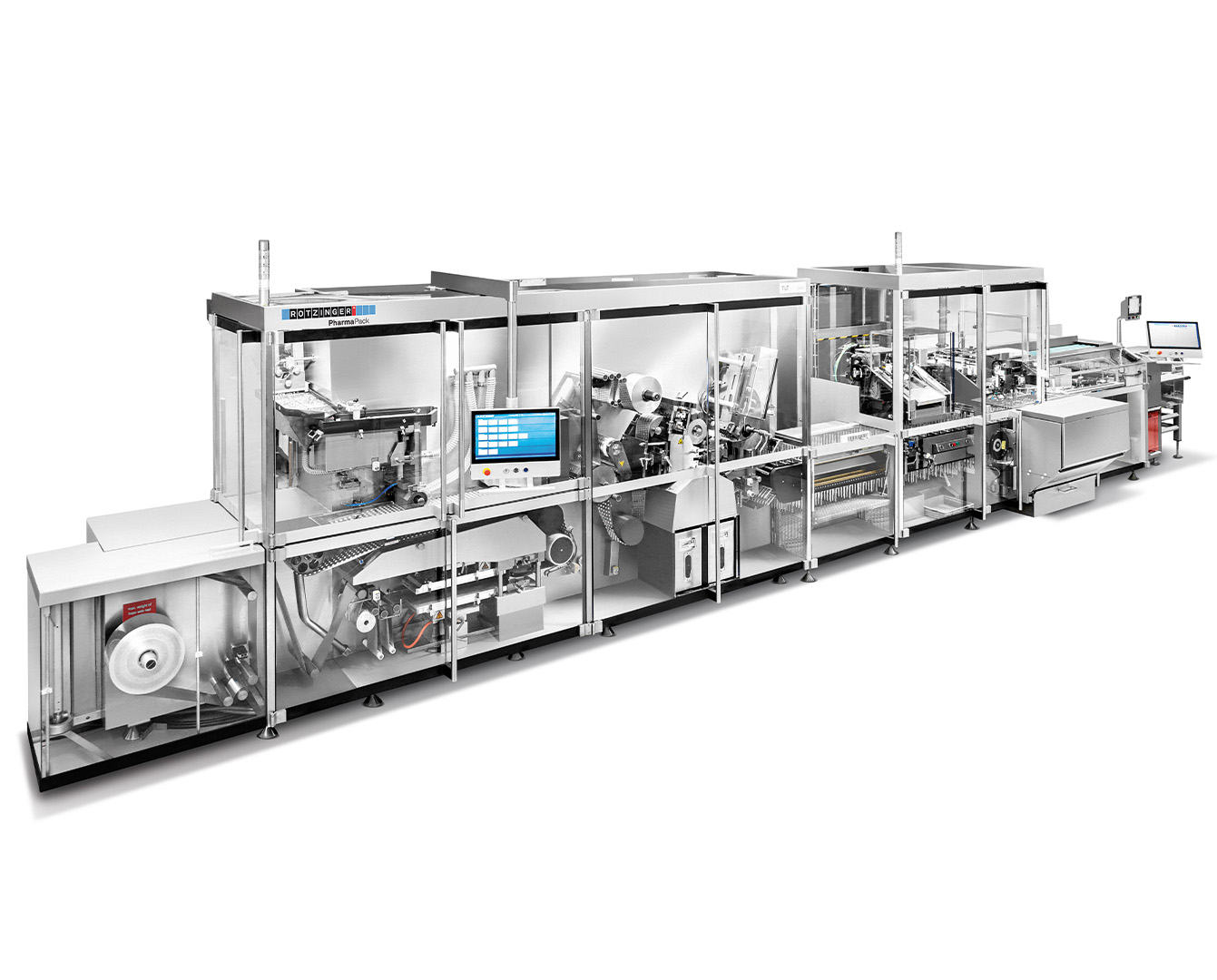

Since then, our development team has been working intensively on our flagship blister machine, the TLT 1400, to meet the new needs of customers and bring the machine up to today's technological standards. The result was the successful "premiere" of our TLT 1400-B at this year's Interpack in May. Many existing TLT 1400 customers had shining eyes and visibly rejoiced at the comeback of this machine legend.

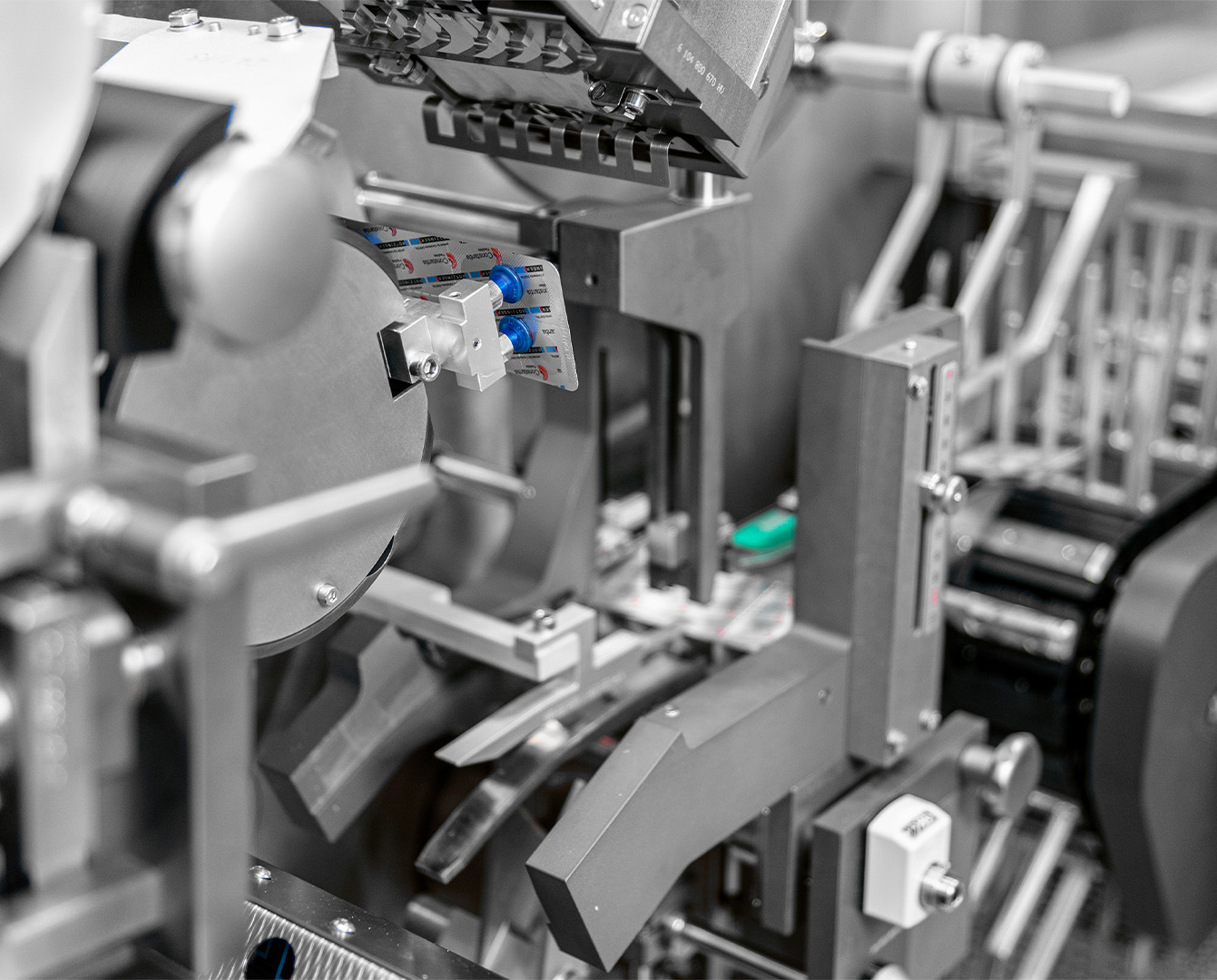

The TLT 1400-B not only represents a state-of-the-art blister machine but also signifies our return to the blister business with existing system solutions. This decision underscores the company's commitment to customer orientation and innovation. The TLT 1400-B impresses with its high system efficiency, process security, and ease of operation. The short HMI-guided changeover times allow flexible adaptation to different product requirements. The cost-effective format parts contribute to the overall efficiency of the Solida packaging lines and set new impulses for sustainability in production.

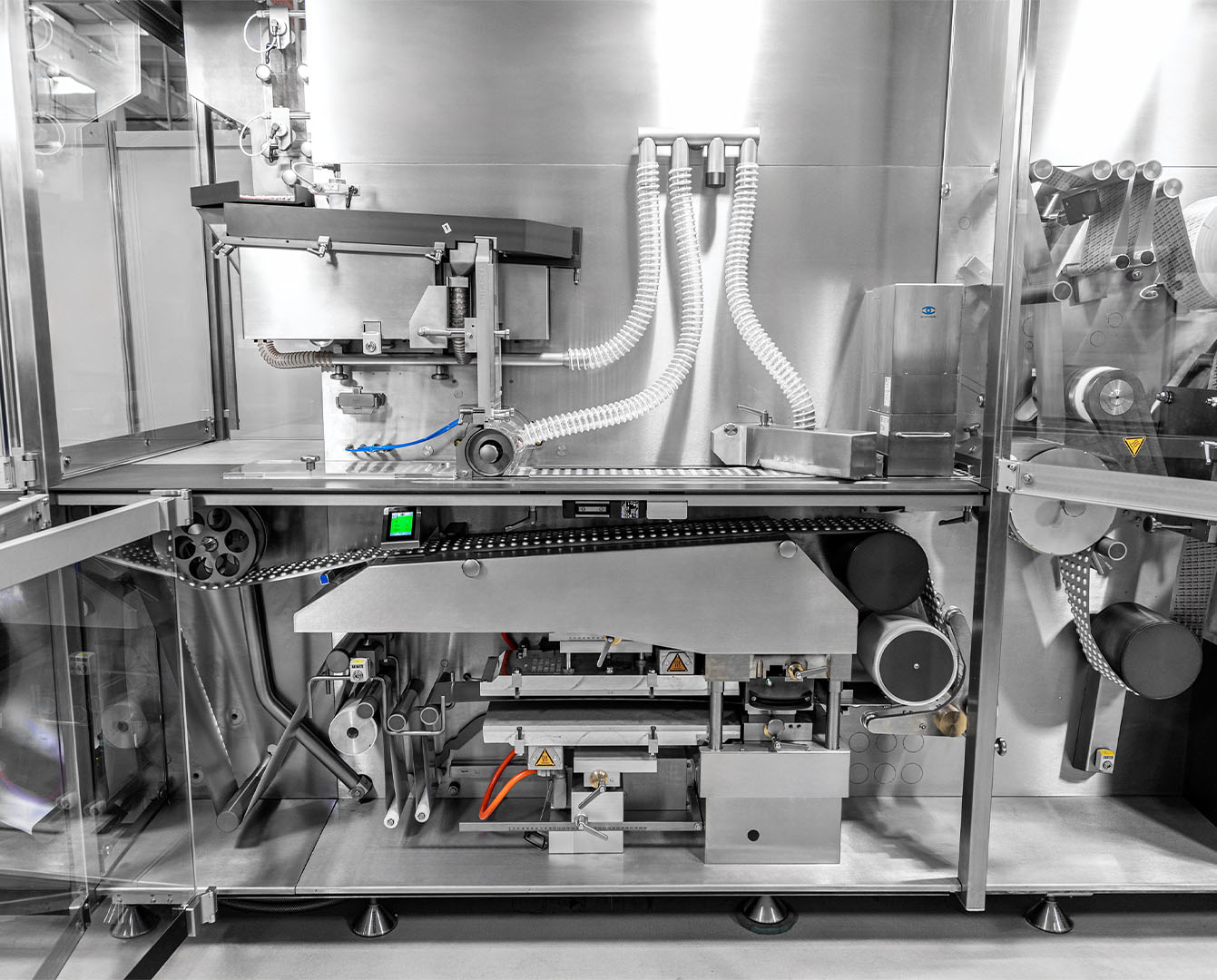

A particular highlight is that old format sets from the previous TLT generation can be used on the current machine. This not only saves costs for customers but also enables a smooth production transition for existing products. The efficient use of existing resources emphasizes our commitment to sustainable production processes. The short changeover times, combined with outstanding performance features, ensure minimal downtime during format changes and enable quick adaptation to changing market requirements. The TLT 1400-B also stands out for its fast installation and commissioning, thanks to a high degree of modularization and standardization. It serves as a model and pioneer for the most advanced procurement and production logistics.

We not only offer automated packaging solutions but also provide optional support and a global network of service products and services. This covers all aspects of the value chain, supporting customers in the advancement and digitization of modern production processes. With three blister machines / lines sold since the market launch, it has been confirmed that the new TLT 1400-B has not lost the charm of past years. We actively took contact with blister customers, listened to their requirements, and are already working on further blister machine concepts. These concepts describe faster but also much smaller machines. You will be surprised.

In a time when not everything new needs to be invented, we demonstrate that adapting existing technologies to current needs can be just as innovative. The TLT 1400-B is not just a machine but a symbol of the connection between tradition, innovation, and continuous progress in the packaging industry.

Since then, our development team has been working intensively on our flagship blister machine, the TLT 1400, to meet the new needs of customers and bring the machine up to today's technological standards. The result was the successful "premiere" of our TLT 1400-B at this year's Interpack in May. Many existing TLT 1400 customers had shining eyes and visibly rejoiced at the comeback of this machine legend.

The TLT 1400-B not only represents a state-of-the-art blister machine but also signifies our return to the blister business with existing system solutions. This decision underscores the company's commitment to customer orientation and innovation. The TLT 1400-B impresses with its high system efficiency, process security, and ease of operation. The short HMI-guided changeover times allow flexible adaptation to different product requirements. The cost-effective format parts contribute to the overall efficiency of the Solida packaging lines and set new impulses for sustainability in production.

A particular highlight is that old format sets from the previous TLT generation can be used on the current machine. This not only saves costs for customers but also enables a smooth production transition for existing products. The efficient use of existing resources emphasizes our commitment to sustainable production processes. The short changeover times, combined with outstanding performance features, ensure minimal downtime during format changes and enable quick adaptation to changing market requirements. The TLT 1400-B also stands out for its fast installation and commissioning, thanks to a high degree of modularization and standardization. It serves as a model and pioneer for the most advanced procurement and production logistics.

We not only offer automated packaging solutions but also provide optional support and a global network of service products and services. This covers all aspects of the value chain, supporting customers in the advancement and digitization of modern production processes. With three blister machines / lines sold since the market launch, it has been confirmed that the new TLT 1400-B has not lost the charm of past years. We actively took contact with blister customers, listened to their requirements, and are already working on further blister machine concepts. These concepts describe faster but also much smaller machines. You will be surprised.

In a time when not everything new needs to be invented, we demonstrate that adapting existing technologies to current needs can be just as innovative. The TLT 1400-B is not just a machine but a symbol of the connection between tradition, innovation, and continuous progress in the packaging industry.