Food & Confectionery

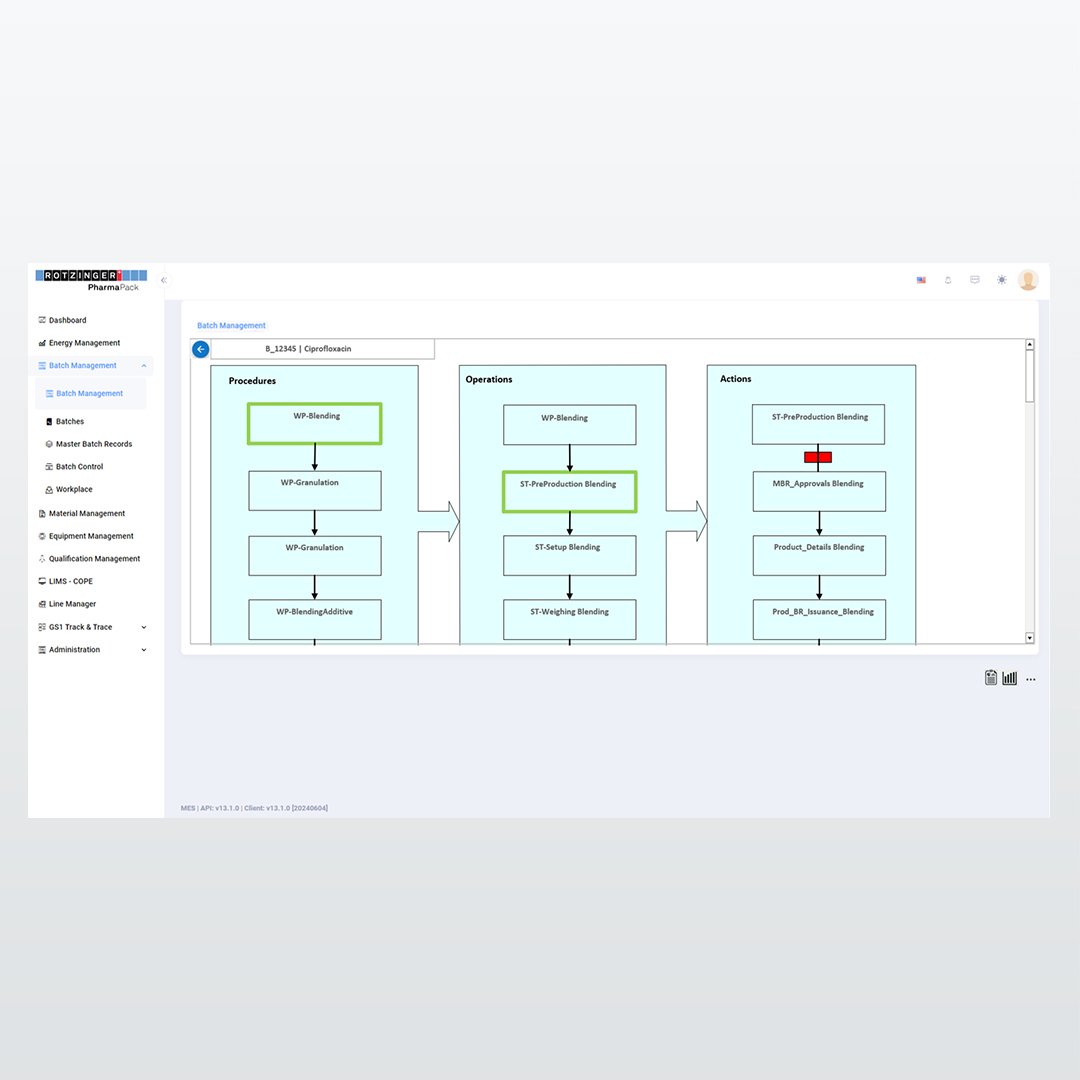

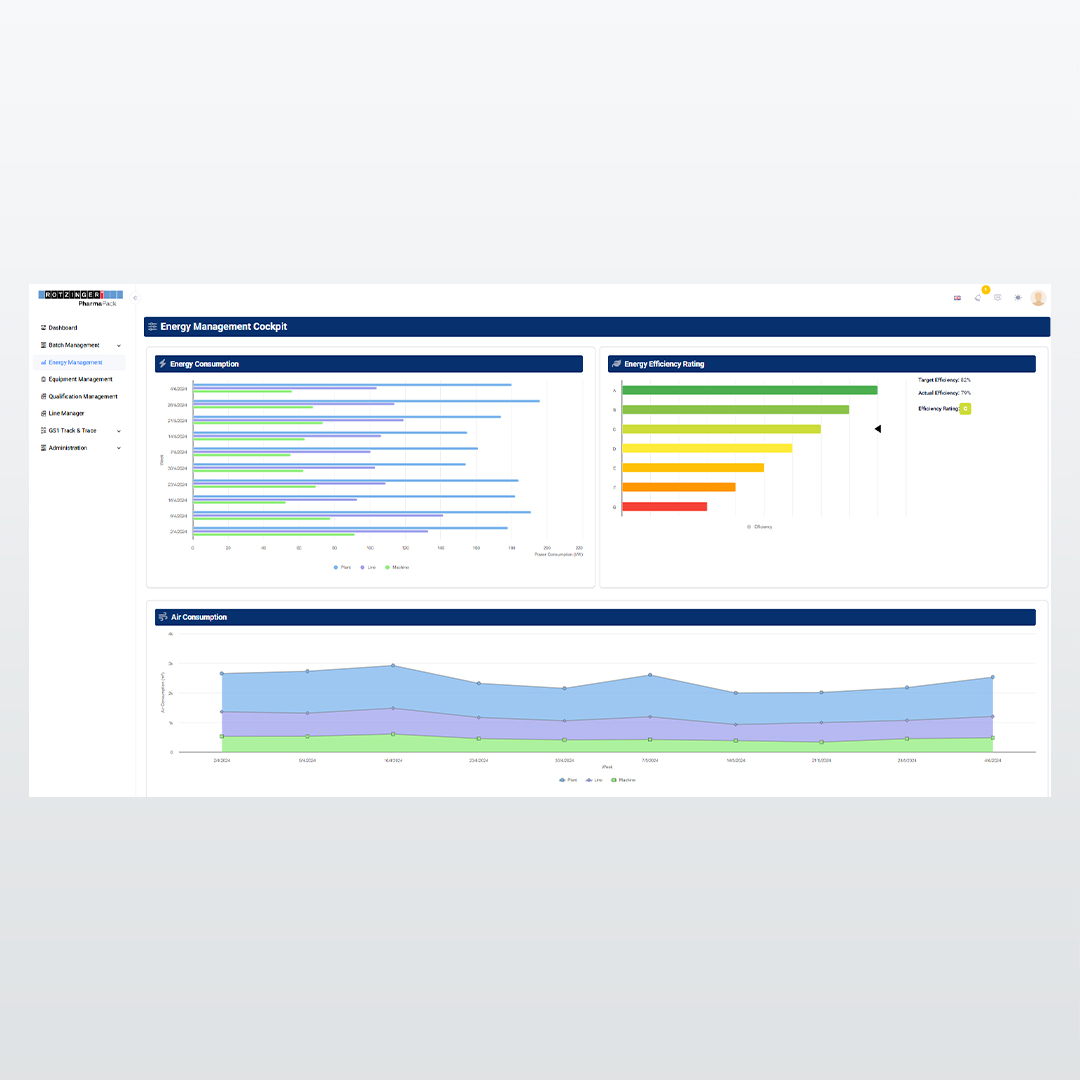

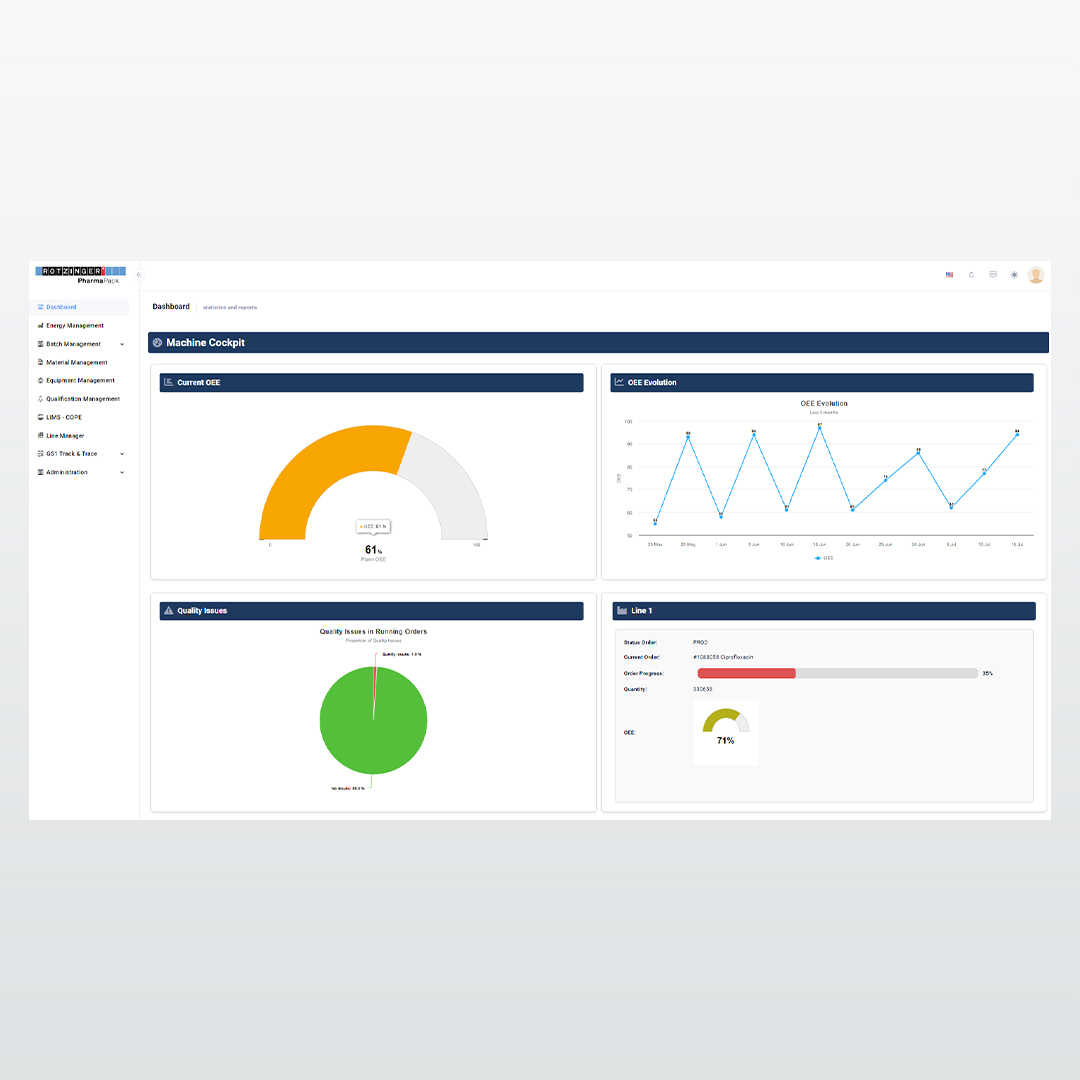

Pharma

Cosmetics

More Industries

Services

Careers

Company

Food & Confectionery

Pharma

Cosmetics

More Industries

Services

Company