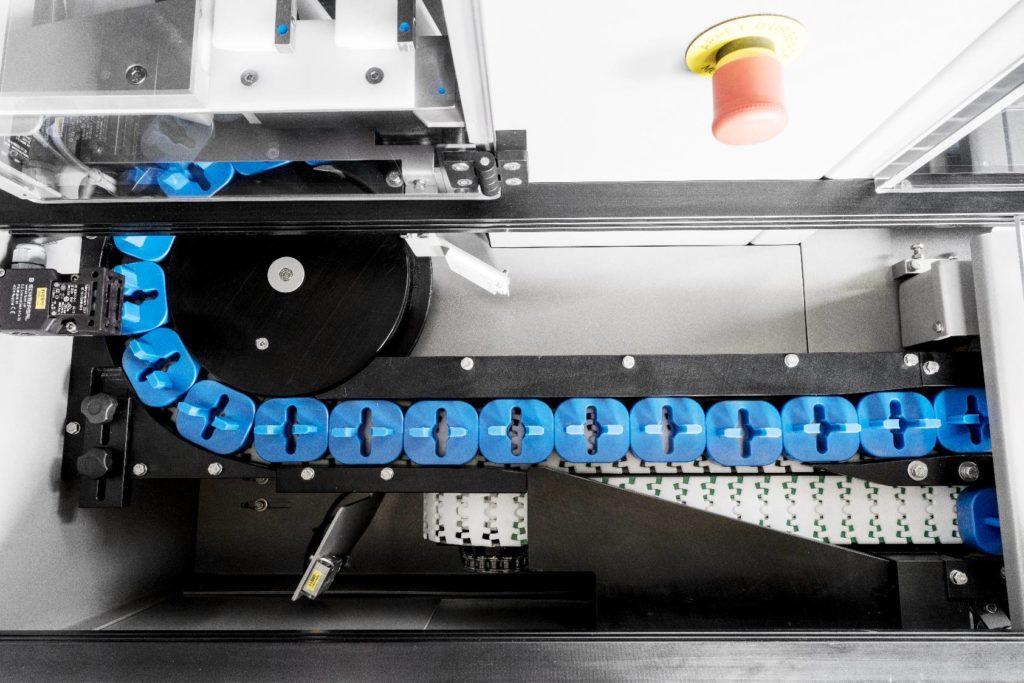

Why is a well-known Central European manufacturer of skin care and other cosmetic products investing for the first time in an in-line bottle unscrambler from Packfeeder, which has been part of the Rotzinger Group since the beginning of this year? Aleix Vives, Sales Director at Packfeeder lists: “Firstly, because of the compact design and thus small footprint, secondly, the machine does not require compressed air, and thirdly, because of our guarantee promise.” In addition, says Aleix Vives, bottle unscramblers of the in-line series are easy and intuitive to operate, guarantee quick and tool-free format changeovers, and are extremely gentle on the bottles. The machine’s vision system also ensures high process reliability.

Packfeeder’s in-line series includes a wide range of models for sorting, erecting and aligning bottles of different dimensions, properties and materials. The speed can be adapted to suit the application and can be up to 500 bottles per minute. The minimum size of the bottles is three to four millimeters, and the maximum is over one liter. In addition to the in-line models, in which the bottles are handled mechanically, Packfeeder also offers systems based on robot technology.

Packfeeder targets its product portfolio to integrators as well as OEMs and contract manufacturers. In addition to single machines, the Rotzinger Group can offer complete lines for the cosmetics industry.