For every production manager in a bakery, it is a horror: mold infestation. Because it means intensive and extensive cleaning, as well as the shutdown of the corresponding production areas, over a painfully long period of time. Any measure that makes this worst-case scenario less likely is a measure that keeps production running.

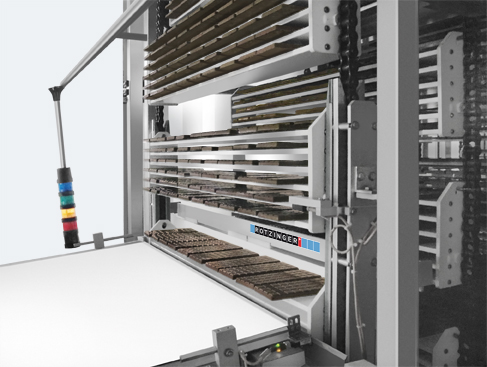

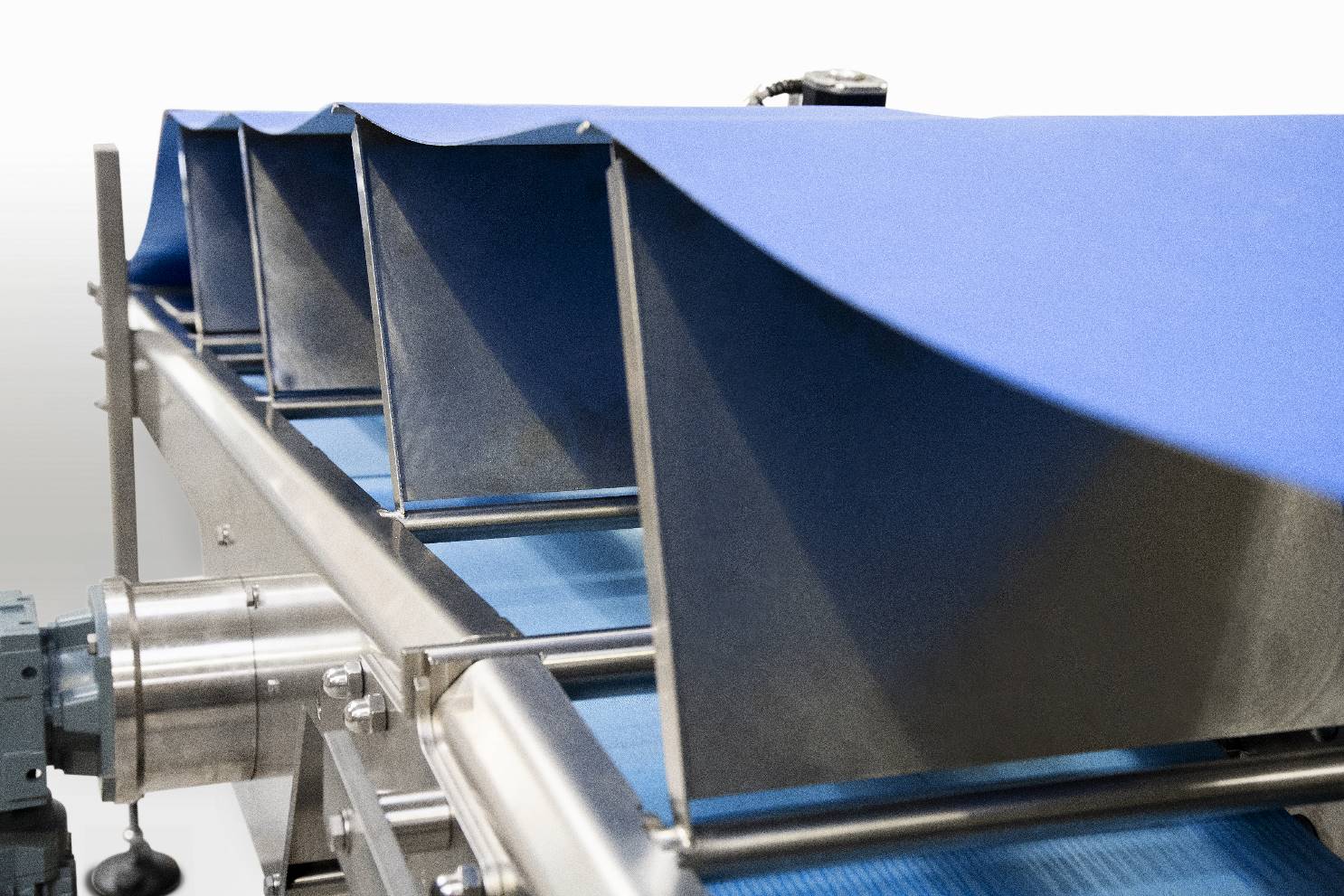

That’s why suppliers like Transver are working hard to make their machines and components even less susceptible to mold. Within the Rotzinger Group, Transver is the competence center for hygienic belt conveyor components and systems. Where could the smallest remnants of baked goods possibly be deposited? How can the design be adapted to reduce even this minimal risk? How can dry cleaning be made even easier? These are the questions that the specialists at Transver are grappling with. And this debate has recently led Transver to introduce a hygienic belt conveyor for bakeries with a number of innovations. Among other things, side panels no longer run horizontally to the belt, but are inclined at 45 degrees to make it easier for crumbs to fall off. A hinged belt support has also been established, which makes cleaning the equipment even easier. Would you like to find out what other measures have been implemented in the design of the new hygiene belt conveyor and how they further reduce the likelihood of mold infestation? We are at your disposal for a consultation appointment.